History

Although there is disagreement on exactly where FIBCs were first used it is certain that they have been employed for a variety of packaging purposes since the 1940s. These forerunners of the FIBC as we know it today were manufactured from PVC rubber and generally utilised within the rubber industry for the transportation of Carbon Black to be used as a reinforcing agent in a variety of rubber products.

By the 1960s development of polypropylene, combined with advances in weaving, the bigbags as we know it today came into being and was rapidly adopted by a wide variety of oil and chemical companies to store and transport powdered and granular products.

It was during the oil crisis of the 1970s that the FIBC really came into its own for transporting huge quantities of cement to the Middle East from across Europe for the rapid expansion of the oil producing countries. At its zenith, upwards of 50,000 metric tons of cement was being shipped out on a weekly basis to feed the vast building programme.

The modern FIBC transports a growing figure of over ¼ billion tonnes of product each year and is used to handle, store and move products as varied as cereals to powdered chemicals and flour to animal feeds. With a capacity of up to 3m³ and load capability ranging from ½ a tonne to two tonnes FIBCs are highly cost effective, easily recyclable and ideal for virtually any free-flowing granule, powder, pellet or flake.

Classification of FIBCs

Construction

-

U-Panel construction

-

Circular construction

-

Baffle construction

-

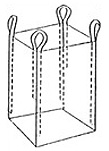

Four side panel construction

-

Round construction

Lifting options

-

Cross corner lifting loops

-

Corner lifting loops

-

Four loops

-

Two loops

-

Sling loops

-

Full loops

Electrostatic properties

-

Type - A - no special electrostatic safety features

-

Type - B - Made from plain (non-antistatic) polypropylene.Type B Bigbags are not capable of generating propagating brush discharges.The wall of FIBC exhibits a breakdown voltage of 4 kilovolts or less.

-

Type - C - Conductive FIBC. Constructed from electrically conductive fabric.A standard fabric is used which contains conductive threads.

-

Type - D - Anti Static. FIBC's essentially refers to those Bigbags which have antistatic or static dissipative properties without the requirement of earthing.

Usage

-

Builder Bigbags or Sand Bigbags

-

Non food grade Bigbags

-

Food Grade Hygienic Bigbags

-

Pharma Bigbags

4 saplı bigbag - standart bigbag :

4 saplı bigbag - standart bigbag :